How to Grind Cannabis for Extraction: A Comprehensive Guide

The cannabis extract sector is one of the fastest-growing segments of the evolving landscape, estimated to reach a value of $56.61 billion by 2032. Unfortunately, with great opportunity comes great competition. To stand out in this landscape, cultivators and manufacturers must produce the highest quality extracts, combining flavor and potency for perfect concentrates.

To ensure a high-quality extract, most companies grind their flower into smaller pieces. However, it’s crucial to attain the right particle size in preparation for the extraction process depending on your method. Grinding plant material too small can result in a low-quality extract with less flavor or potency. However, particles that are too large can significantly reduce the total cannabinoid content in the finished product. Research has revealed that smaller particle sizes generally lead to higher retention of terpenes and cannabinoids.

Finding the right balance requires careful consideration of multiple factors, from the properties of your cannabis flower to your extraction process. Here, we’ll take a closer look at the steps involved in grinding cannabis for top-quality extracts.

The Importance of Proper Grinding

Grinding cannabis for extraction is distinctly different from using a grinder to prepare plant material for use in a joint or bowl. The right particle size for your pre-roll won’t necessarily be ideal for your extraction method.

When you grind cannabis with an industrial mill or cannabis grinder in preparation for extraction, you increase the surface area, helping the solvent access the terpenes and cannabinoids quickly. If you are extracting using a solventless method, grinding can be helpful for using certain micron bags or filters. An effective grinding process before extraction helps to preserve potency, while reducing the presence of undesirable residue in your extract, such as chlorophyll.

Various pieces of research suggest that smaller particle sizes of ground cannabis often equate to a higher total yield. However, when using solvents for extraction, grinding your cannabis buds too small may decrease the selectivity of the solvent. In some cases, this can be a good thing, depending on the solvent type. A smaller grind size speeds up the action of CO2, but for a powerful solvent like ethanol, grinding too fine can lead to the contamination of the product with additional plant material.

A coarse grind, or no grind, on the other hand, will require more time to achieve the same extraction results. Again, depending on the solvent, this can be a good thing, reducing the risk of pulling out too much wax or chlorophyll.

For solventless extraction, the particle size plays a crucial role in the quality and yield of the final product. When using specific micron filters or bag sizes, tailored particle size allows for capturing the most trichomes while preventing contamination with plant material, which can affect both taste and potency.

Connect with an expert today.

The Extraction Process and Its Impact on Particle Size

With all cannabis extraction methods, grinding your cannabis plant material to the ideal particle size is crucial to producing a high-quality extract, combining flavor and potency, and reducing the number of undesirable compounds such as plant waxes and chlorophyll.

Each extraction method has its own advantages and drawbacks, which can influence your decision to use a coarser or finer grind. Here’s a guide to the most common extraction methods and how they may influence your grind choices.

Ethanol Extraction and Particle Size

Cannabis and hemp should be milled to a particle size of 5/64” – 1/4” for ethanol extractors.

Ethanol is a powerful and efficient solvent for cannabis and hemp extraction. It is a food-grade solvent, effective at separating terpenes and cannabinoids from cannabis plants at high volumes.

Extraction is quick, occurring in as little as 15 minutes. The process is best performed at lower temperatures, so there is less co-extraction of undesirable compounds from the ground flower.

For ethanol extraction, a coarse grind is often best. Some producers may choose not to grind plant material at all. This is because a larger grind size combined with lower temperatures helps retain the cellular structure of the plant material, improves cannabinoid extract, and reduces the need for post-processing.

Additionally, since ethanol’s boiling point is higher than that of hydrocarbons, this may expose your plant mass to more heat. Too much heat reduces the concentration of terpenes in your final product, particularly if your grind is extremely fine. It can also produce cruder extracts with higher numbers of unwanted components, such as plant wax and chlorophyll.

One of the main benefits of ethanol extraction is that it can significantly increase production capacity. The proper particle size can help decrease the solvent necessary per pound of ground cannabis. When plant material is ground into smaller pieces, more material can fit in the extraction vessel per run, ultimately increasing production speed and reducing the ethanol that needs to be distilled in post-processing.

CO2 Extraction and Particle Sizes

Cannabis and hemp should be milled to a particle size of 1/16” – 3/16” for CO2 extractors.

Supercritical CO2 or carbon dioxide extraction is often considered one of the most environmentally friendly and non-toxic solvent solutions for cannabis extraction. It generally doesn’t leave behind residual compounds and is commonly used in food and beverage manufacturing.

During the CO2 extraction method, supercritical CO2 is washed over cannabis buds, allowing it to seep through the biomass and separate THC, CBD, and other desirable components. Subcritical CO2 extraction offers a similar result but requires lower temperature and pressure parameters.

Grinding cannabis to a smaller particle size when using a CO2 extractor helps to pull out beneficial cannabinoids and terpenes at lower pressures without the need for terpene-compromising high temperatures. Since CO2 extractors run at extremely high pressures (approximately 2,000 PSI), the movement of the solvent through the material column can create channeling when the grind isn’t consistent or the particle size is too large.

When this happens, the solvent cuts channels through the material, leaving some areas of the plant material or cannabis bud untouched and under-extracted. The solution to the problem is a smaller, more consistent grind.

Notably, one of the reasons there’s such a narrow range of ideal particle sizes for CO2 extraction is that it’s a highly versatile solvent. Additionally, it’s worth noting that as objectives vary from producer to producer, so does the plant material. Some strains may require smaller pieces and longer runs, while other high-potency strains may do better with a larger size and shorter runs because they extract more easily.

Another reason is the desired purity of the extract itself. Shorter runs with a larger particle size yield a better extract—but less of it. On the other hand, smaller particle sizes have been shown to increase overall yield. That said, particle size will affect the overall yield depending upon what solvent is implemented in extraction.

Hydrocarbon Extraction and Particle Size

Cannabis and hemp should be milled to a particle size of 5/64” – 1/8” for hydrocarbon extractors.

Hydrocarbon extraction is among the most popular and effective solvent-based extraction methods. Hydrocarbons such as propane and butane are solvents made from decayed organic materials, and they are often used in the food processing industry.

Hydrocarbons like propane and butane feature a low boiling point, which allows extractors to use lower temperatures throughout the extraction process. This increases the chances of a full-spectrum extract. Hydrocarbon yields can also be significantly higher than supercritical CO2 extraction methods.

Hydrocarbons like butane and propane are powerful solvents, but because the solvent flows through the ground cannabis under pressure, channeling can occur the same way it does during CO2 extraction. While this channeling problem is less severe with hydrocarbon extraction, it’s still best to avoid large particle sizes or unground material.

Notably, the perfect particle size to grind cannabis and hemp for a hydrocarbon extractor can be a bit larger or smaller, depending on the strain. However, the sweet spot for hydrocarbon extraction is a fine grind of 5/64” – 1/8”.

Solventless Extraction and Particle Size

Solventless extraction is an alternative method for separating trichomes, however, there’s no one-size-fits-all guide for the ideal particle size for it. Your grinding process will depend on the extraction method you’re using, and the size of the bags and filters.

Solventless cannabis products are becoming increasingly popular. This category grew in value between June 2021 and June 2022 at an average of 132% per month.

Solventless extraction methods replace solvents with agitation or low heat and pressure to separate trichomes from the plant material. Agitation methods like ice water extraction are particularly popular in the evolving solventless extract space.

For an in-depth look at ice water extraction, see our related article explaining the finer details of making bubble hash.

Additionally, heat and pressure extraction, used to create rosin, can be ideal for companies creating edibles, tinctures, and topical products. However, these methods can require additional equipment, such as a rosin press. These methods may also require a finer grind, to help improve the separation of terpenes and trichomes.

Other Factors to Consider When Grinding Cannabis for Extraction

The extraction method you choose for your cannabis product will have a direct impact on whether you should choose a finer grind or a larger grind. However, there are other factors to consider too. Before placing your flower into a grinding chamber or mill, think about:

- Heat: Exposure to excessive heat can diminish the flavor of terpenes and break down trichomes in your cannabis plant. An extraction method that utilizes higher temperatures, like ethanol, can therefore require a larger grind. However, it’s worth remembering your grinding mill can also generate unwanted heat, which can damage your product. Ensure you’re choosing a mill that preserves the compounds in your cannabis flower.

- Consistency: Consistency is important to preserving the same level of terpenes and cannabinoids throughout your extracts. Any lack of consistency in your grind can influence the results of your extraction method and lead to problems with your product’s flavor and potency. This means it’s important to choose a grinder that includes precisely sized apertures in the screen, for exceptional particle distribution.

- Grinding method: The grinding method you use is influenced by the kind of grinding machine or mill you choose. Some grinding tools shred the plant material down to size, which can damage plant compounds and lead to the deterioration of terpenes. These mills may also leave behind more undesirable components. A more effective solution will grind your plant material against milling screens, to deliver a specific particle size, while minimizing unwanted substances.

Choosing a Grinder For Quality Extraction

Once you’ve determined your extraction method, and the ideal particle size for your grind based on your goals, the next step is choosing the right cannabis grinder. The correct grinder or mill is crucial to ensuring you can effectively prepare your plant material for extraction. If you want to extract the purest, highest-quality oils, you need the right machine.

A quality cannabis grinder or mill will ensure you can achieve a consistent particle size and consistent quality in your cannabis product. It also ensures you can maintain the crucial cannabinoids and terpenes you want to extract from your cannabis bud. A quality grinder will support the preservation of delicate trichomes, ensuring consistent potency, aroma, and flavor.

Some of the key factors to look for in a quality grinder include:

- Stainless steel material: Some grinders use nylon whips, similar to a weed eater. These whip grinders aren’t ideal as they can destroy precious cannabis compounds. The nylon can also wear and break down, contaminating the ground flower. The highest quality cannabis grinder will be made from 100% stainless steel construction, including the screens, which are responsible for most of the grinding.

- Consistency: A high-quality commercial cannabis grinder guarantees a consistent grind and uniform particle size with each batch of processed plant material, ultimately ensuring efficient extraction. Ensure your grinder or mill pushes the product through precisely sized apertures in the screen, to improve consistency in particle distribution.

- Low heat output: A high-quality cannabis grinder is designed to generate minimal heat through a slow and steady grind speed. More aggressive, high-friction grinders produce more heat, which can damage trichomes and decrease the potency of your product. Low heat allows for greater trichome retention, which helps maintain optimal cannabinoid and terpene levels. Lower heat is a direct result of a lower-speed motor. While a faster motor speed may save time, it ultimately reduces the quality of your product.

- Variable grinding options: A quality grinder will be equipped with variable speed operation and screen configurations that can be used with any strain and different moisture levels to offer consistently uniform particle size and minimal trichome dust.

- GMP Compliant: Good Manufacturing Practice (GMP) has become the industry standard for quality assurance. The highest-quality cannabis grinders are compliant for integration into GMP-certified facilities, which ultimately ensures that cannabis products are consistent and safe to consume. They will also be easy to disassemble and quick to clean to maintain sanitary standards.

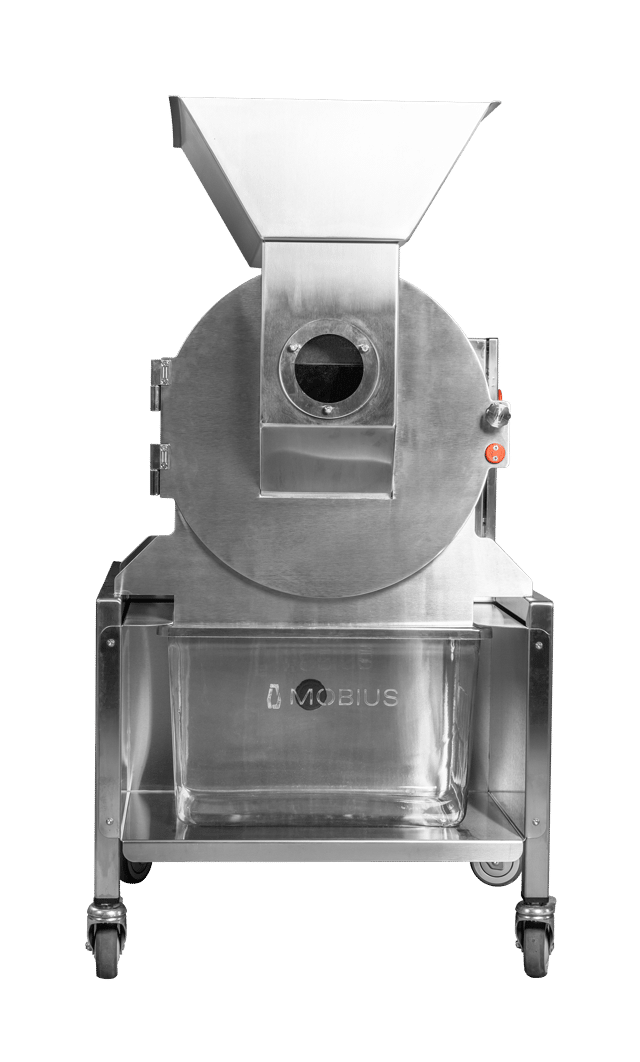

The Mobius M210 Mill: The Ultimate Commercial Grinder

The Mobius 210 Mill is one of the only purpose-built grinding machines specifically designed for processing cannabis. This intuitive solution features all the key elements you need from a mill intended to grind plant material for extraction. It features a stainless steel construction, and a low-RPM churn rate to minimize destructive heat.

Notably, while the machine is low-RPM, the ½ horsepower impeller motor is still extremely efficient, capable of milling more than 110 lbs of product per hour.

The Mobius M210 Mill delivers a consistent particle size and is compatible with dry flower, fresh frozen, and even trim for pre-rolls. The Mill offers excellent customization with five different milling screens available, and custom sizes for any specific milling needs. Additionally, cultivators can choose from specific configurations for optimal CO2, ethanol, solventless, and hydrocarbon extraction.

The M210 Mill can be fully automated to boost the efficiency of your production processes, and is fully GMP-ready, for exceptional compliance. The stainless-steel mill is easy to clean between batches, and it was even designed with operator safety in mind, featuring adjustable controls, an emergency stop, and a safety interlock solution.

What’s more, the solution comes with four locking casters for easy movement and positioning. If you’re looking for an efficient grinder solution to enhance your extraction creation process, add the M210 to your operation.

Alternatively, if you’re looking for a smaller-scale solution, the M60 Mill offers the same incredible features as the M210, for smaller-scale production needs.

Final Thoughts

High-quality extraction is dependent on a high-quality grind. Knowing how to grind cannabis for efficient extraction offers a better understanding of how imperative it is to invest in a commercial grinder.

When it comes to grinding flowers for different cannabis extraction methods, size does matter.

Consistently achieving a uniform size best suited for your preferred type of extraction, whether ethanol, hydrocarbon, CO2, or solventless, makes all the difference between a potent, pure oil and a subpar product.

Elevate your extraction process by consulting a Mobius representative about the M210 Mill. Schedule a consultation today.

Frequently Asked Questions

Do grinders crush trichomes?

High-quality grinders are designed with trichome retention in mind. The Mobius M210, for example, uses an ultra-low speed motor that generates minimal heat to reduce trichome loss and powder, unlike high-friction grinders that contribute to the reduction of trichomes.

Do you remove stems before grinding?

Plant material should be bucked, trimmed, and cured before grinding, so the larger stems and branches are removed. When using the Mobius M210 Mill, there is no need to remove additional small stems before grinding to the desired particle size.