Hot Swap Kit

Extra parts for continual trimming

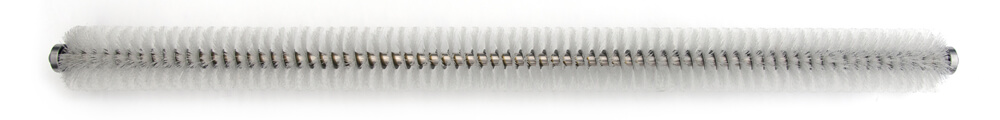

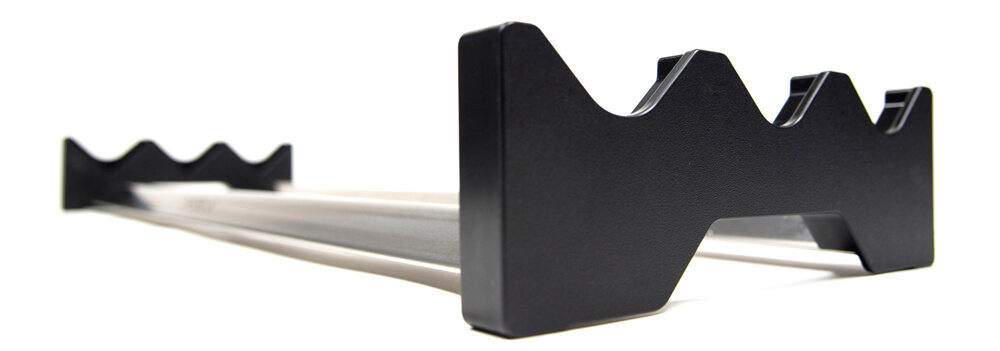

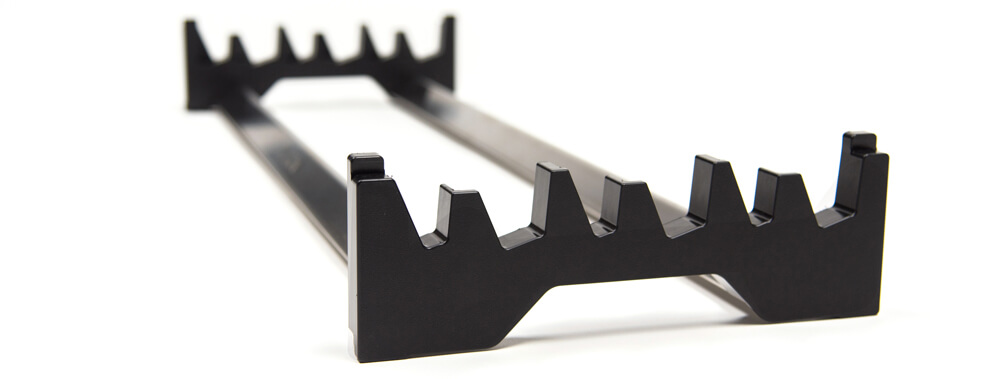

What I’m most impressed with is the thought, design, and engineering of the M108S. I have worked on multiple pieces of high-quality machinery over the years in different industries, and I know quality and ease of use when I see it. This is by far the best cannabis trimmer I have used. The ease of assembly and disassembly is a treat. Now that I have streamlined our cleaning process, the turnaround time is quick. The “Hot Swap” kit was worth the extra to be able to change the blades and tumbler after four hours of running.

–

JEFF COLLETT

HEAD OF SECURITY, DUNESBURRY FARMS